Evaluating the crushing strength of paper, paperboard, and corrugated board is a critical step during production. Since paper fibers are blended in varying proportions and orientations, it is essential to understand how these variations influence the performance of the final product.

Crush testing is far more than a simple compression test. Depending on the product type, strength evaluation can be carried out in seven standardized ways using a Crush Testing Equipment (Model: UEC-1026BII). These include:

- Ring Crush Test (RCT)

- Flat Crush Test (FCT)

- Edge Crush Test (ECT)

- Concora Crush Test (CCT)

- Concora Medium Test (CMT)

- Pin Adhesion Test (PAT)

- Score Quality Test (SQT)

Each of these standardized methods reveals a unique aspect of the paper or board’s strength, showing how effectively the fibers are bonded and how they behave under load. The data obtained from these tests enable manufacturers to fine-tune production parameters, ensuring an optimal balance between cost, performance, and durability in the final paper or packaging product.

Conducting crush tests in accordance with test standards requires specialized tools and fixtures to ensure accuracy, consistency, and repeatability. Each test begins with the precise preparation of specimens, as sample dimensions directly influence the reliability of test results. Samples are first cut to exact dimensions defined by the respective test standard. Precision cutting eliminates dimensional variations that could otherwise affect the outcome. To achieve this, specially designed cutters are used — enabling fast, accurate, and repeatable specimen preparation.

Once prepared, the sample is mounted in a dedicated test fixture that holds it securely and ensures proper alignment throughout the test. These fixtures play a vital role in maintaining test integrity, ensuring results remain consistent and comparable across different laboratories and paper mills.

Our Lab Crush Tester (Model UEC-1026BII) is equipped with a complete range of such accessories, simplifying specimen preparation and improving test reliability. The following highlights the accessories and procedures used for each crush test.

Ring Crush Test (RCT)

The Ring Crush Test is a widely used method for assessing the edgewise compressive strength of paper and paperboard. In this test, a sample is shaped into a ring and placed into an annular groove of a specially designed fixture. Axial load is then applied until the sample fails. This test, like the others, helps manufacturers optimize material design by providing insights into its load-bearing capacity and resistance to external stresses. For accurate preparation, the Punch & Die Cutter (Model UEC-1009 CI) is used to cut rectangular samples measuring 12.7 × 152.4 mm, as specified in the standard for the Ring Crush Test.

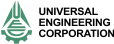

Edge Crush Test (ECT) & Flat Crush Test (FCT)

The Edge Crush and Flat Crush Tests are important tests for assessing the compressive strength and durability of corrugated board. Corrugated board consists of two main components: linerboard and fluting medium, both made from high-strength kraft paper. The linerboard forms the smooth outer and inner faces, while the fluting medium is corrugated into a wave-like pattern and sandwiched between the liners to create a lightweight yet rigid structure.

Edge Crush Test (ECT)

The Edge Crush Test measures the material's compressive strength when loads are applied parallel to the fluting. This test simulates real-world stacking conditions, where boxes experience edgewise compression during handling and storage. The results provide insights into the load-bearing capability and stacking strength of the finished box.

Before performing the test, samples are precisely cut using the ECT Cutter (Model UEC-1006 CI). The cutter prepares specimens of 25.4 mm or 50.8 mm width and 100 mm length. The exact dimensions depend on the test standard and flute type—for example, Flute A requires a square specimen of 50.8 × 50.8 mm. The sample is then held between two aluminium support blocks during testing.

Flat Crush Test (FCT)

The Flat Crush Test evaluates the compressive strength of corrugated board under loads applied perpendicular to the fluting. This test primarily assesses the crush resistance of the fluting medium, which contributes significantly to the board’s cushioning and protective properties.

Specimens for the FCT are prepared using the FCT Cutter (Model UEC-1003B), which produces circular test samples of paperboard or corrugated board. The cutter is available in multiple configurations, allowing preparation of samples with surface areas of 32.3 cm², 50 cm², 64 cm², and 100 cm² to match various test standards.

Prepared samples for the Flat Crush Test (FCT) do not require a dedicated specimen holder. Once cut to the specified dimensions, the samples can be tested directly for compressive failure. However, precise alignment is essential for accurate and repeatable results. The sample must be placed centrally between the upper and lower compression platens to ensure uniform load distribution during testing.

To assist operators, some Crush Testers are equipped with alignment markings or reference guides on the platens, enabling quick and accurate positioning of the test specimen. This simple yet effective feature minimizes human error and enhances the consistency and reliability of test data.

Concora Medium Test (CMT) & Concora Crush Test (CCT)

CMT and CCT tests are widely used for checking the compressive strength of fluting medium. Flutes play an important giving a cushioning layer that absorbs impact and provides rigidity, while also enhancing the board’s stacking strength without increasing weight or material cost. The fluting profile for these tests is produced using the Concora Medium Fluter (Model UEC-1025). A kraft paper sample, typically cut using the Punch & Die Cutter (Model UEC-1009 CI) designed for Ring Crush Test specimens, is inserted between two heated corrugating rolls. These rolls shape the paper into a uniform wavy (fluted) pattern, simulating the actual corrugated medium used in board production.

The standard fluter configuration produces an ‘A’-type flute, while other flute profiles can be provided upon request to match different testing standards or production requirements.

Once fluted, the sample is inserted in the respective test fixture for evaluation. The Concora Crush Test (CCT) measures the crushing force applied parallel to the fluted strip, assessing the edgewise compressive strength of the corrugated medium while the Concora Medium Test (CMT) determines the crush resistance when the load is applied perpendicular to the flutes, representing the flatwise compressive strength of the medium.

Pin Adhesion Test (PAT)

It is also important for manufacturers to assess the bond of the liners and flutes to ensure the structural integrity of the box. The Pin Adhesion Test (PAT) evaluates the bonding strength between liners and the corrugated medium by measuring the force required to separate the liners from the fluting medium. This is useful in identifying manufacturing defects like poor adhesive penetration or low bond strength.

The PAT method involves securing a sample in the test fixture. A pin-type probe applies a controlled force to detach the liner from the flute. The peak force recorded during separation indicates the adhesion strength of the board. Results are compared against test standards to assess the results and address any issues, thereby ensuring that the paperboard products meet required quality and performance standards. A specialized sample holder, selected according to the flute type, is used to ensure proper positioning and accurate measurement during testing.

Score Quality Test (SQT)

Assessing the bending and folding of a paperboard sample gives crucial insights into its performance and durability. The Score Quality Test (SQT) involves pressing a creasing line into the sample to facilitate folding, allowing the measurement of the score break force for both scored and unscored sections. These measurements help calculate a score ratio, which is then used to determine whether the material meets pass or fail criteria. The results ensure that paperboard and cardboard meet the required standards for applications involving folds and creases. Strong performance in this test indicates that the material is reliable and functional for practical use in packaging, construction, and similar applications.

The tools and fixtures form an integral part of the Lab Crush Tester, enabling each test to be performed with the highest levels of accuracy, precision, and ease of operation. As the demand for safe, durable, and high-performance packaging continues to rise, evaluating the failure points of liners, flutes, and corrugated boards has become an essential step in ensuring product reliability and quality.

This testing equipment is especially valuable for Packaging and Printing Manufacturers, Corrugated Box Producers, Paper Mills, as well as Consumer Goods, Logistics, and E-Commerce companies. By providing clear insights into material performance, the Lab Crush Tester helps manufacturers enhance strength, optimize material use, and reduce production costs.

If you are looking to invest in a high-quality Lab Crush Tester, we invite you to contact us through our Contact Us page to learn more about our complete range of testing solutions.