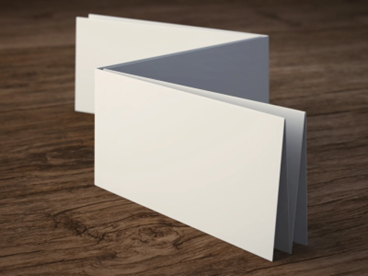

Foldability or Folding endurance refers to the ability of the paper to withstand repeated folds under controlled conditions before it finally breaks. It is a physical property testing parameter that determines if the paper can resist constant folding, bending, and creasing. Papers that are frequently subjected to this action are most tested for this property. These papers include currency notes, newspapers, wrapping papers, maps, archival documents, etc. Folding endurance also helps manufacturers study how paper ages, both before and after being exposed to accelerated conditions. It clearly shows how strong and durable the paper is. Less folding endurance means quicker aging and deterioration of the paper, while a higher value indicates slower aging and deterioration.

Folding endurance is largely dependent on how well the paper is refined during the papermaking process. As refining increases, the fibers fibrillate and bond more tightly, improving the paper’s flexibility and strength — and therefore, its ability to withstand repeated folding. However, the addition of non-fibrous materials such as fillers, pigments, or sizing agents can reduce folding endurance by making the sheet stiffer or more brittle.

To maintain a balance between mechanical performance and production cost, it becomes essential for paper manufacturers to test the foldability of their paper and ensure it meets the mechanical requirements for its intended application — whether for printing, packaging, or currency paper.

What Is a Folding Endurance Tester?

The most reliable way to determine this property is by using a Folding Endurance Tester. This laboratory instrument measures how many times a paper strip can be folded back and forth under controlled conditions before it breaks. The test result, known as folding endurance, is expressed as the logarithm of the number of double folds sustained before rupture.

Factors like grain direction with respect to the folding line, kinds of fibers, fiber contents, specimen caliper, etc., determine the number of double folds a specimen can bear. In addition to this, the test method used to test the property also determines the number of double folds. Hence, knowing about the different testers is a must to derive accurate results.

Types of Folding Endurance Testers

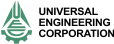

It is important to understand that all types of Folding Endurance Testers operate on the same fundamental principle — repeated double folding of a paper strip under controlled conditions until it ruptures. The number of folds sustained before failure represents the folding endurance of the sample.

While the underlying concept remains the same, there are subtle design and operational differences among the instruments. Each type was developed by different inventors to serve specific testing needs, materials, and precision levels.

The Folding Endurance Test can be performed using any of the following standard instruments.

-

Schopper Folding Endurance Tester

-

MIT Folding Endurance Tester

-

Kohler Molin Folding Endurance Tester

Schopper Folding Endurance Tester (UEC-1007 BI)

The Schopper Folding Endurance Tester is designed to evaluate the folding endurance of all types of paper, films, and foils up to 0.25 mm thickness. Engineered for efficiency, the tester enables simultaneous testing of two specimens, ensuring higher productivity and reliable comparative results. Its user-friendly touch screen interface offers a seamless testing experience — allowing users to view results in multiple languages, save test data, and transfer it easily to their PC. The smart control system automatically calculates and displays the folding endurance value based on the number of double folds along with statistical data, providing fast, accurate, and repeatable results every time.

MIT Folding Endurance Tester (UEC-1007C)

The MIT Folding Endurance Tester operates on the principle of repeated double folding under a specified tension and folding radius. This tester is ideal for thicker or stiffer materials, such as kraft paper, currency paper, cardboards, and coated sheet samples where higher folding stress and tension are required.

The instrument clamps the specimen between two jaws and repeatedly folds it back and forth through 135° to 180°, until it ruptures. The machine counts the total number of double folds and records it automatically. The test parameters — including folding angle, tension, and speed — can be adjusted as per test standards. Its robust design provides reliable performance, and adjustable testing parameters make it a preferred choice for quality control laboratories and R&D departments seeking to evaluate mechanical performance under flexing stress.

Kohler Molin Folding Endurance Tester (UEC-1007A)

The Kohler Molin Folding Endurance Tester is another standardized instrument used primarily for thin and flexible papers. It performs the folding test under precisely controlled load, speed, and angle, providing highly accurate endurance readings.

This tester’s design focuses on sensitivity and precision, making it suitable for research laboratories and paper mills where accurate fiber bonding and flexibility assessments are required. Its automatic counter, digital display, and programmable settings make it a dependable tool for routine testing as well as material development studies.

Looking to Invest in a Folding Endurance Tester? Make the Right Choice with UEC

-

Schopper Type — Best for precision lab testing of fine papers at moderate speeds. Widely used in quality control labs and can test two specimens simultaneously.

-

MIT Type — Best for industrial testing of strong/thick materials like packaging board. Allows control over testing speed, tension, and angle.

-

Kohler Molin Type — Best for high-precision lab work, under precisely controlled folding stress, speed, and angle, providing highly accurate endurance readings. Excellent for research and quality comparison.

By selecting the appropriate type of Folding Endurance Tester — whether Schopper, MIT, or Kohler Molin — manufacturers and quality control laboratories can ensure that their materials meet the required performance standards. Regular testing helps in maintaining consistent product quality, optimizing refining and filler levels, and achieving the ideal balance between strength, cost, and usability. For further questions, visit the contact us page.