Packaging design and manufacturing mistakes can cost heavily to every component of the distribution cycle, i.e., the packaging manufacturer, businesses, as well as end customer. While it damages the business’s reputation in the customer’s eyes, it also disappoints businesses against the manufacturer. Ultimately, the whole chain gets disturbed, and the businesses have to find other packaging manufacturers.

However, if the manufacturers can avoid the following mistakes, they can save their venture from possible disasters. Let us look at these mistakes.

3 Major Packaging Mistakes That Manufacturers Must Avoid

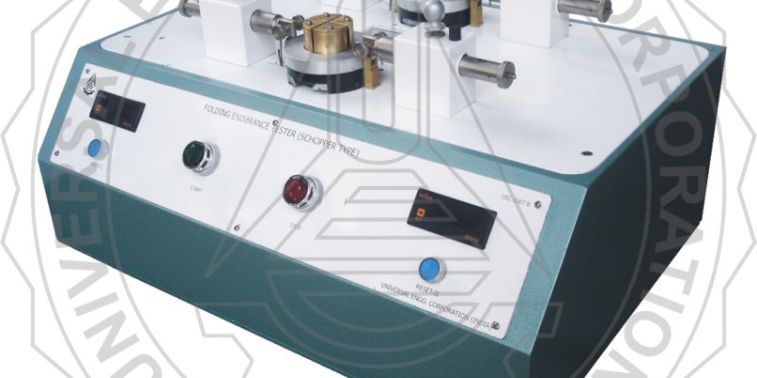

- No Package Testing

Equipment like impact tester, box compression tester, drop tester, abrasion tester, scuff tester, bursting strength tester, etc. are extremely useful in testing the quality of the packaging materials. By using these machines, manufacturers are able to evaluate different parameters of the packaging paper and board and take control measures wherever required.

However, several manufacturers choose not to test packaging materials, which is why they do not invest in package testing equipments. This may either be because they are small-scale businesses and could not afford to invest in these instruments, or they are just reluctant to do so. But, just like every product needs proper testing before it reaches the market, the packaging materials deserve it too.

Proper evaluation helps manufacturers know if their products are capable of serving the required objectives, whether they are composed right, and if they are able to cater to the needs of their customers. If yes, it may provide them with high goodwill and an increased number of customers.

- Opting For Poor Quality Materials

This could turn out as a side effect of not using packaging testing equipments. When manufacturers avoid using these instruments, they remain unaware of the fact that they might not be using the right quality materials, resulting in poor-quality packaging. They are not able to examine the performance of materials, which is why they constantly offer poor-quality packaging to their customers.

These materials can easily damage or break products that are fragile. As a result, the resources are wasted, the manufacturer’s reputation is damaged, and customers are lost. Hence, choosing the right raw materials should be their priority.

- Overlooking The Needs Of Customers

Some packaging manufacturers forget to pay heed to the end customer’s needs. They believe that it is only the product inside the box that matters to the customers. Yes, the product does matter, but what matters to contemporary customers in addition to the product is its packaging. This is because a package not only safeguards the products but also explains a lot about the business’s morals, objectives, and concerns.

Today’s customers are highly interested in knowing about businesses’ gestures towards many things besides just the product. Hence, it is indeed important to comprehend their needs and interests before developing packaging materials.

So these were the main mistakes that packaging manufacturers often made, but should avoid at all costs. From using performance-driven package testing equipments to choosing high-quality raw materials and comprehending the customer needs, manufacturers can take the right steps towards avoiding mistakes and achieving success. UEC takes responsibility to manufacture and provide quality packaging testing machines to packaging businesses. Connect now to know more.