A package goes through a number of external forces during shipping, handling, and warehousing. The most common among them is the compression force, as it is no wonder that packaging boxes with be stacked on top of each other during the above-mentioned processes.

This is what makes it one of the biggest challenges for the manufacturers. And to overcome this challenge manufacturers and laboratories perform box compression strength tests. Compression testing of packaging (corrugated & non-corrugated) material is conducted to determine its resistance to outer compressive load or force.

In this test, the deformation of the specimen or other behavior is observed under compression. Compression strength is a crucial factor in the design of the packaging material. This is why it is performed as a part of the design process in either the production environment or under quality control conditions of the laboratories.

A box compression tester is an equipment that determines the compression strength of corrugated or non-corrugated box material. It helps manufacturers evaluate if the box is safe and has enough integrity to hold and carry the products inside without damage.

Besides the overall box quality, batch quality, and design procedure can be judged using this tester. Manufacturers can even ensure compliance with the industry and international standards by performing the compression strength test.

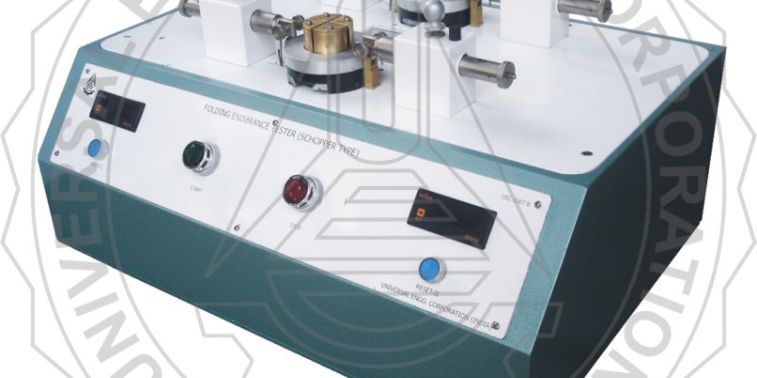

Box Compression Tester By UEC

The box compression strength tester by UEC is among the most sought packaging testing machines by paper & packaging manufacturers. It is widely used to determine the compression resistance, deformation, and stack force resistance of corrugated boxes or cartons.

Manufacturers make use of this crucial machine to also decide if a specific box is suitable for the intended use. Let us learn what advantages it serves to the manufacturers.

Benefits of UEC’s Box Compression Tester

- User-Friendly Machine

UEC is renowned to make user-friendly testing machines and this is on the top of those. All you have to do is place the corrugated box specimen in the center of the lower plate.

During the test, the upper plate will move downward and apply a specific pressure on the specimen. As soon as the unit will detect damage or breakage of the specimen, the upper plate will go back to its original position.

- Custom-Made Design

What’s best about this tester is that it can be custom-made for corrugated boxes or mono cartons as per the manufacturer’s preferences.

- Versatile Usage

We must mention that this reliable tester is designed and manufactured as per industry and international standards to measure the compressive strength of different packages.

These include paper boxes, paper cases, cartons, beehive crates, and also paper tanks in addition to the corrugated boxes.

- Result Accuracy

The compression testing unit just like any other machine by UEC gives accurate test results. It is fitted with a digital display that shows the compression load and deformation of the specimen.

Moreover, its microprocessor-based circuit allows retaining of the peak value, automated to normal zero setting, overload, and over transit protection features.

- Collection Software

We offer a special software on-demand for test data collection and analysis. This software is accessed using a computer to get parameters like maximum & minimum values, peak values, arithmetic mean, the graphical result of load and deformation, coefficient of variation, etc.

This is the packaging compression tester that manufacturers require if they are seeking the most accurate results. Besides the box compression testing machine, UEC houses numerous packaging testing machines.

These include a puncture resistance tester, drop tester, package shaker, core compression tester, impact tester, and so on. Get in touch to source high-quality and performance instruments for your manufacturing business.