Folding endurance refers to the ability of the paper to withstand folds before it finally breaks. It is a paper physical property testing parameter that determines if the paper is able to resist constant folding, bending, and creasing.

Papers that are frequently used are most commonly tested for this property. These papers include currency notes, newspapers, wrapping papers, maps, archival documents, etc. The folding endurance also lets manufacturers examine the aging characteristics of a paper, before and post an accelerated environment.

Plus, it is a clear indicator of the durability of the paper that is tested. Less folding endurance means quick aging and deterioration of the paper, while a higher value indicates slower aging and deterioration.

Folding endurance is based on the refining of the paper. It enhances with the increased refining of the paper. On the other hand, the addition of non-fibrous additives like fillers, sizing, etc. on the surface of the paper reduces its folding endurance.

Whatever the desired folding endurance intensity, it is based on the ultimate use of the paper. Now how to test if the paper has sufficient folding endurance for the desired use? The answer is to use a folding endurance tester.

What Is A Folding Endurance Tester?

A folding endurance tester is a paper physical property testing equipment that tests the above-mentioned folding endurance parameter of the paper for end use.

Factors like grain direction in respect to the folding line, kinds of fibers, fiber contents, specimen caliper, etc. determine the number of double folds a specimen can bear.

In addition to this, the type of folding enduring tester used to test the property also determines the number of double folds. Hence knowing about the tester is a must to derive accurate results.

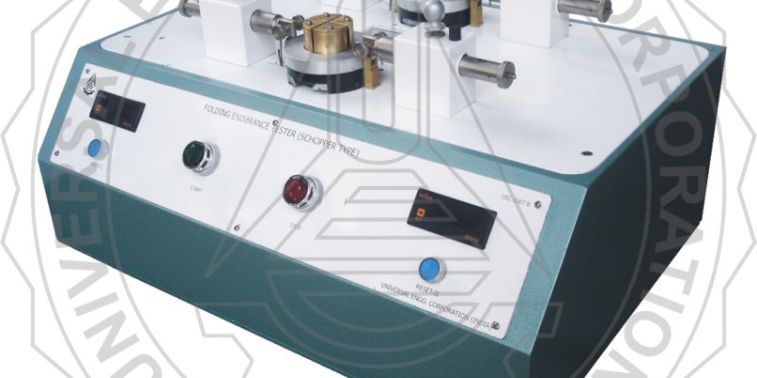

UEC houses the Schopper-type folding endurance testing machine that assesses all types of paper, films, and foils up to 0.25 mm thickness. By testing on this machine, the manufacturer can not only determine the fold endurance but also the actual strength of the paper. It consists of the following components:

- The size of the main unit (along with the cover) is 45*40*45 cm.

- It weighs approx. 34.5 kilograms.

- Applicable under standards: SCAN P 17:77, TAPPI T 423/453 & TAPPI T453/511

- Can test newsprint paper, writing, and copier paper.

- The unit consists of 2 horizontally and oppositely located clamping jaws. These jaws are easily movable and can hold a sample of 15*100 mm under different tension levels during the folding process.

- The slotted folding blade folds the paper by sliding back and forth between 4 creasing rollers. The folding speed is 1120 double folds per minute.

- The loading clamps of the spring type force a standard pressure of 1000 grams while the test proceeds.

- The digital counters come with a 5-figure display, have hold and zero settings, and showcase the test result at the break.

- Manufacturers can opt for a punch n die sample cutter so that they can easily cut the specimen to get accurate results.

Looking To Invest in a Folding Endurance Tester?

If yes, then it is time to get in touch with experts at UEC. We are the leading manufacturers, suppliers, and exporters of paper physical property testing machines.

Trusted by numerous paper manufacturers and laboratories, UEC plays its part in boosting the productivity of businesses by offering cutting-edge testing equipment. Connect with us to invest in high-performance and accuracy-driven machines.