Crush tests are crucial to determine the strength of paper, boards, fiberboard, and corrugated boards. These tests help manufacturers measure the amount of weight the material’s edges can withstand. This helps in further understanding if the boxes made of these materials can withstand the weight of the contents during edgewise compression.

If you’re a corrugated box or paperboard manufacturer, these tests are mandatory for you. This is because a box undergoes many ups and downs during shipping and handling, which are usually rough. Hence, it is important for them to invest in a crush tester, sourced from a reliable manufacturer/supplier.

UEC is a leading manufacturer and supplier of crush testers and other paper testing instruments in India. Paper and board manufacturers from across the nation source high-quality testing instruments from UEC at the most affordable rates. In the following article, we will learn about the 3 most popular laboratory crush testers UEC offers in the industry.

- Crush Tester with digital display

- Crush Tester with LCD display & keypad

- Crush Tester with touchscreen feature

3 Most Popular Lab Testers For Accurate Evaluation of Crushing Strength

1. Crush Tester with digital display

- This crush tester is designed to accurately test the compression/crush strength of materials like paper, board, fiberboard, and corrugated board.

- Users can perform the following tests on this high-quality tester:

- Ring crush test

- Edge crush test

- Corrugated crush test

- Flat Crush test

- Corrugating Medium Test

- On small packages or mono cartons, this tester is used to perform compression tests.

- This crush tester is provided with a load range of 0-200 kilogram-force (kg f).

- It has a digital display feature, which lets the user see the result directly on the panel.

- The main unit also comes with an RCT sample holder and a removable disc. These components are designed for a sample thickness of 0.15 to 0.49 mm.

- Paperboard manufacturers must opt for a sample strip cutter to enable a damage-free cutting of specimens and accurate results.

Other info:

- Model No. - UEC-1026 A

- Weight - 34 kilograms

- Dimensions - 37.5 x 35 x 53.5 centimetres

- Applicable Standards - ASTM D-1164-53, ASTM D-1125-54, and TAPPI T-472 m-51.

2. Crush Tester with LCD display & keypad

- The third model of laboratory crush tester is keypad operated. It is also designed to accurately test the compression/crush strength of materials like paper, board, fiberboard, and corrugated board.

- Users can perform the following tests on this high-quality tester:

- Ring crush test

- Edge crush test

- Corrugated crush test

- Flat Crush test

- Corrugating Medium Test

- On small packages or mono cartons, this tester is used to perform compression tests.

- The main unit also comes with a keypad, with which it is operated with ease. The connected LCD panel displays the test results.

- This laboratory crush tester is also provided with a load range of 0-500 kilogram-force (kg f).

- The RCT sample holder and 8 removable discs are designed for a sample thickness of 0.15 to 0.49 mm.

- Users can also opt for an inbuilt thermal printer along with the unit, to print the test results. And, to transfer the test data into a personal computer, they must opt for an apt communication port and data transfer software.

- For the preparation of samples, manufacturers can opt for high-quality sample cutters.

Other info:

- Model No. - UEC-1026 BI

- Weight - 61.2 kilograms

- Dimensions - 54.5 x 37.5 x 64 centimetres

- Applicable Standards - APPITA/AS 1301.449 and FEFCO No.50

3. Crush Tester with touchscreen feature

- The touch screen crush tester is designed to accurately test the compression/crush strength of materials like paper, board, fiberboard, and corrugated board.

- Users can perform the following tests on this high-quality tester:

- Ring crush test

- Edge crush test

- Corrugated crush test

- Flat Crush test

- Corrugating Medium Test

- On small packages or mono cartons, this tester is used to perform compression tests.

- The edge crush tester is provided with a load range of 0-500 kilogram-force (kg f).

- The main unit also comes with a touch screen (or HMI) panel. This panel, which, with a single touch operation, provides the graphical and numerical representation of the results.

- The RCT sample holder and 8 removable discs are designed for a sample thickness of 0.15 to 0.49 mm.

- Users can also opt for an inbuilt thermal printer along with the unit, to print the test results. And, to transfer the test data into a personal computer, they must opt for an apt communication port and data transfer software.

Other info:

- Model No. - UEC-1026 BII

- Weight - 61.7 kilograms

- Dimensions - 54.5 x 37.5 x 64 centimetres

- Applicable Standards - APPITA/AS 1301.449 and FEFCO No.50

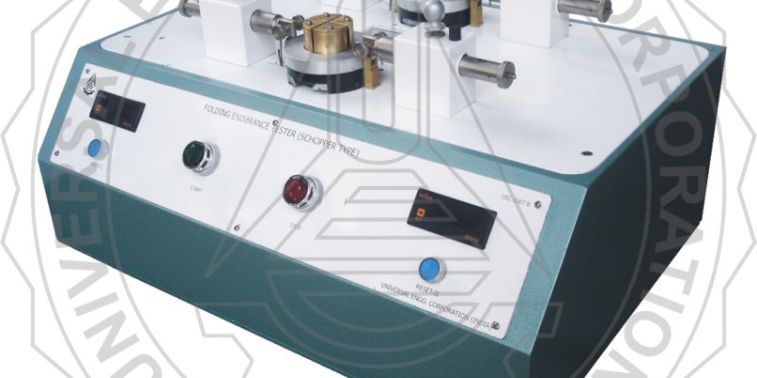

4. Laboratory Crush Tester

Crush tests play a significant role in comprehending the strength of paper/board, corrugated boxes, and similar materials. Not only that, but these tests also define the shortcomings of the materials. Hence, by conducting the tests, the design, quality, and compression strength of these materials can be known and improved in time. Both manufacturers and customers can leverage its benefits, and UEC wants them to have these perks.

UEC, therefore, houses high-performance crush testers for contemporary manufacturers and customers. Visit the UEC website, www.uecin.com, and connect with our experts to learn more about paper testing equipment. Drop inquiries and request demos to make an informed decision.