When it comes to understanding the printing response and results of the paper, we often consider printing inks, printing press being used, and of course the human factors as significant aspects.

However, in addition to these factors, the paper’s absorption, thickness, and permeability also influence the printing outcomes. To examine these factors, paper manufacturers, printers, and lithographers, require high-performance and high-accuracy surface testing instruments.

UEC understands this need and therefore manufactures vital surface coating and printability testing instruments.

In the following article, we will throw light on the 6 popular surface coating and printability testing equipment.

6 Surface Coating & Printability Testing Equipment By UEC

- Paper Testing Wax Sticks

Paper testing waxes are used to measure the surface strength of the paper or board or how well it resists picking on the surface. The wax sticks are designed as per TAPPI T 459 om-93 standard and are used to test the surface strength of only coated and uncoated papers/boards.

Manufacturers cannot test loosely felted papers or papers crafted using thermoplastic resin coatings, using these waxes.

- Set of Wax Sticks

These waxes are non-oily waxes, made with hard resin, and possess a high level of adhesion. Each set by UEC is identified by a code and contains a series of wax sticks, with a cross-section of 18×18 mm.

The numerical code of each series is set as follows: 2A, 3A, 4A, 5A, 6A, 7A, 8A, 9A, 10A, 11A, 12A, 13A, 14A, 16A, 18A, 20A, 23A. In every wax box, you will find 8 wax sticks of a specific numeric code from the above.

- Test Procedure

To perform the test, the operator heats the waxes and apply on the specimen’s surface. When this applied wax cools down, the operator pulls it from the surface.

A higher wax pick number suggests stronger surface strength and that the wax will pick less fibre from the surface.

- Patra Type Fluff Tester

The fluff tester by UEC determines the short fibers or linting tendency of uncoated printing paper. Linting refers to the tendency of an uncoated paper to lose materials/fibres during offset printing. The Patra-type fluff tester, designed on the PIRA concept, accurately determines this tendency.

Test Procedure

The fluff tester simulates the movement of the printing press using a dry blanket and is able to give reproducible results. To perform the test, the operator places the specimen between the offset blanket and a steel roll.

Placed under a nip pressure, the specimen is then moved between the rolls. The moving magnifying glass mounted on the tester, counts the number of fluff particles and fibres sticking to the offset blanket.

The test is performed as per standard SCAN-C 33:80 on the Patra-type fluff tester. Newsprint, writing paper, and printing/copier paper can be tested for fluff using this equipment.

- GFL Type Fluff Tester

The GFL-type fluff tester is another kind of fluff testing machine that is motorized and contains components like a water container, a steel roll, and a rubber roll.

Test Procedure

The specimen is placed between the steel and rubber rolls and moved to perform the test. During the test, the operator transfers the fluff particles or fibers on the moistened steel roll and then washes the fluff off from the steel roll and gets them in the water. Now, the suspended fluff is filtered using black filter paper and then dried to measure the actual fluff.

Newsprint, writing paper, and printing/copier paper can be tested for fluff using the GFL-type fluff tester.

- Bar Coater

The wire bar coater is a vital surface coating instrument by UEC that contains a wire wound bar or Mayer bar to perform the traditional coating technique.

It is a motorized unit, that comes with a mounting offset blanket, offering a coating area of 27x15 cm. Along with this, the unit consists of 7 coating rods to offer different coating thicknesses.

Test Procedure

The wire wound bar or Mayer bar is a steel bar surrounded by a wire. It is the wire’s diameter that determines the thickness of the coating. Moreover, it is the viscosity of the coating, the required coating thickness, and the speed of coating that together determines the choice of wire’s diameter.

To perform the coating, the Mayer bar applies a uniform coating on the substrate under precisely controlled conditions. Typically, paints, printing inks, adhesives, starch, and varnishes are used for coating purposes. The coating speed is set between 2 and 15 mm per minute, because of which the coater is able to provide a uniform coating to the substrate.

Writing paper, printing/copier paper, duplex, and art paper can be coated using this instrument.

- Laboratory Calendaring Machine

UEC’s lab calendaring machine is designed to perform calendaring trials and experiments under laboratory conditions. The unit comes with:

- A robust base

- An electrically driven pump

- A stainless-steel roller, which is heated electrically and operated thermostatically.

- Three roller stacks, each having a face width of 300 mm.

- A hydraulic cylinder, that adjusts the line pressure between 0-100 kg/cm2.

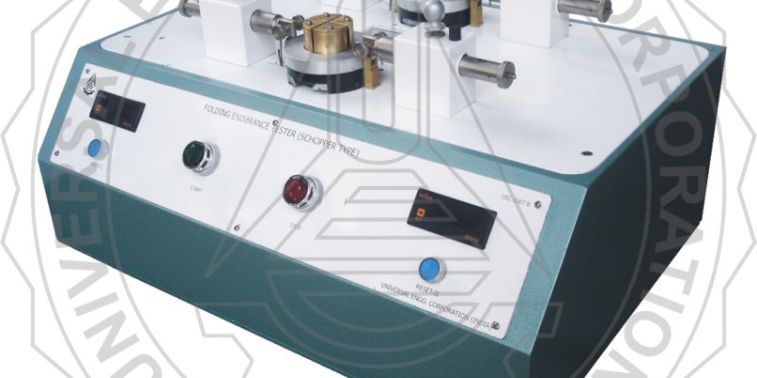

- Digital Printability Tester

The printability tester by UEC is digital equipment designed to test paper and ink in a lab, in simulating conditions to actual offset letterpress printing. Besides, letterpress printing, it also determines precise simulation of gravure and flexo printing on the lab scale.

The equipment is electrically driven and comes with two printing discs, a variable interval timer as well as variable speed and printing pressures.

It is capable of testing the paper surface strength just like paper testing waxes. Plus, it also evaluates aspects such as abrasion, and print penetration among others.

Moreover, the unit comes in two variations. The single-shaft unit is manually operated, while the motorized unit comes with two shafts.

Manufacturers must opt for inking apparatus to distribute the ink evenly on the printing disc and a sample preparation cutter to prepare test specimens.

So, these were the six vital surface coating and printability instruments by UEC. We are leading manufacturers of pulp, paper, packaging, surface coating, and printability testing instruments in India. If you’re looking to invest in high-performance and accuracy-driven machines for your paper manufacturing business, get in touch with us for more details.