Cow dung or cow manure is nothing but the waste product of cows. Primarily used as an agricultural fertilizer, cow dung is rich in minerals and can also be utilized in producing biogas. However, what many of us may not know is that cow dung can be used to manufacture natural or prakratik paints. And in the following article, we are going to learn about the steadfast prakratik paint manufacturing process.

Why Cow Dung for Eco-Friendly Paint Manufacturing?

The cow has religious significance among the Indians. While we consider the cow as our mother, we also value her milk to be the healthiest thing to drink on the earth. But, what also proves immense significance is the cow dung. And this importance is not just from the religious or cultural point of view, but also from the scientific point of view. Just like cow’s milk, cow dung has a lot to offer. A few advantages are listed below.

Benefits of Cow Dung

- It is affluent in natural nutritious elements, such as vitamins, minerals, lignin, mucus, cellulose, hemicellulose, oxygen, nitrogen, potassium, and carbon.

- Consists of many helpful microbes, such as Bacillus, Lactobacillus, Candida, Saccharomyces, Streptococcus, and so on.

- Acts as the energy source for cooking food, especially in rural areas. Biogas or gobar gas plants can work significantly as an energy source. Plus, cow dung also helps produce methane gas, to further generate electricity.

- Works as the best fertilizer for agriculture.

- It has antibacterial and antifungal benefits and also helps in destroying microbes present in the air.

- It is environmentally friendly, cost-effective, and supports human health and wellness.

- Its fiber-rich content is used to manufacture papers.

Among the several benefits that cow dung offers to nature, people, and processes, an emerging perk is the cow dung paint manufacturing process.

Cow Dung Prakratik Paints & Their Benefits

The concept of manufacturing cow dung paints is derived due to the numerous benefits cow manure offers to us. It also takes inspiration from the ancient method of painting walls, ceilings, and floors with cow dung. The only difference is that earlier people used to coat raw cow manure on their home’s surfaces, and now they have a modified version of it. This needs no mentioning that these paints are both eco-friendly, cost-effective, and are a result of a reliable prakratik paint manufacturing process. Let us look at the benefits of these paints.

- Cow Dung Paints Are Environmentally-Friendly

The cow’s manure is the fundamental component in prakratik paints. Hence, unlike the other prevailing paints that harm the environment, cow dung paints support the environment.

- They Are Antibacterial & Antifungal

Due to their natural antibacterial and antifungal qualities, these paints prevent the growth of fungus and bacteria on surfaces, unlike prevalent paints.

- Free From Toxins

Prevalent paints often contain toxic chemicals like Glycol, Xylene, Methylene Chloride, and Ethyl Acetate. This is not the case with cow dung paints. They are typically a composition of cow dung, lime, neem leaves, pigment colors, thickeners, binders, and other natural extracts.

- Have No Odor

The cow dung paint manufacturing process does not promote the inclusion of unwanted and additional fragrances. It results in odorless paints that are safe for human lungs and overall health.

- Has High Heat Resistance

Prakratik paints are made of only natural elements, which is why they are high resistant to heat, unlike the prevalent ones.

Cow Dung Prakratik Paint Manufacturing Process

In this section, we will learn about:

- Raw materials and machines used to manufacture cow dung paints, and

- Prakratik paint manufacturing process

Raw Materials

The following raw materials are commonly used in the manufacturing of natural paint:

- Cow Dung

- Color Tint/Pigment

- Thickening Substance

- Binding Agent or Binder

- Other Additives

Machinery

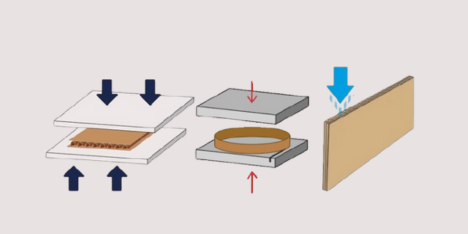

Several paint manufacturers make use of UEC triple disc refiner to prepare the required mixture of cow dung. The machine converts the manure into a pulp and refines it to make the final prakratik paint.

Cow Dung Paint Manufacturing Process

The following is the step-by-step process to manufacture the prakratik or cow dung paints.

- First, the cow dung is accurately refined using a tri-disc refiner or double-disc refiner. Here, the cow dung is combined with water to achieve the right mixture.

- The liquid mixture then undergoes bleaching, to turn it white. Sodium hydroxide and hydrogen peroxide are used to do the bleaching. After the bleaching, the cow dung transforms into CMC or Carboxymethylcellulose (a mandatory step in the manufacturing of paints).

- After this, calcium carbonate or lime is added to the mixture.

- Once the lime gets mixed into the liquid, the operator adds the binder, to bind all the elements together and make the cow dung paint ready for use.

Conclusion

So, this is how the cow dung paint manufacturing process takes place. In the above article, we learned about the significance of cow dung and prakratik paints, and the process of manufacturing them using the right raw materials as well as the machine. UEC is a leading cow dung refiner manufacturer, supplier, and exporter in India. If you’re looking to start your natural paint manufacturing business, it’s time to visit our website and get in touch with us for your inquiries.