Acrylic emulsion paints are among the most preferred choices for interior and exterior walls. Not just that, these paints also find applications on canvas, furniture, and many other surfaces. These paints are water-based and comprise pigments, coagulants, and emulsifiers in addition to water. The emulsifiers emulsify the dispersed pigments in water, which is why these paints are popularly known as emulsion paints. These paints are predominantly used by the population and hence produced in tremendous quantities by acrylic paint manufacturers.

It is good to know that the market size of Acrylic Emulsions is expanding at a significant rate. It is expected to reach $15.5 Billion by 2030 from $8.12 Billion in 2021, suggesting a substantial CAGR of 7.5% between 2021-2030.

As a leading acrylic paint plant manufacturer, UEC provides high-performance acrylic paint plant machinery to manufacturers across the world. With a rise in the demand for these paints, the need for manufacturing plants is accelerating too. This is why we are developing steadfast, high-quality, and accuracy-driven paint manufacturing plants and machinery on an extensive level.

Let us now know in-depth about acrylic emulsion paints and comprehend their manufacturing.

Key Features of Acrylic Emulsion Paints

Unlike oil-based paints, acrylic emulsion paints work as a better solution for interior and exterior surfaces. A majority of homeowners find these paints a suitable and efficient option for their homes as it offers the following characteristics/benefits.

- Highly Durable Finish

Acrylic emulsion paints lend high durability and a long-lasting finish to the surfaces. The cross-linking polymers in these paints make the applied layer strong and non-porous, resulting in a long-standing paint. This is why most homeowners prefer them for both interior and exterior walls.

In addition to offering durability, these paints are also resistant to mildew and molds. Hence, this way they become an ideal paint for bathrooms, kitchens, garden areas, and other spaces where moisture can develop.

- Easy to Clean

Emulsion paints are easy to clean. Any stains on the surfaces can be removed with easy washing, giving a whole new appearance to the surface.

- Less Odor

When acrylic paints are developed in paint plant machinery, low levels of VOC or Volatile Organic Compounds are used. Hence, these paints do not emit too many chemicals when applied to the surfaces. Less chemical emittance means less odor or fumes, hence the most suitable choice for those overly sensitive to paint’s odor.

- High Shine

When used specifically on furniture or decorative assets, acrylic paint can come up with a good shine and a wonderful finish. Besides, these paints come in two varieties, one for exteriors and the other for interiors. The exterior paint gives a high level of shine to the walls and comes in gloss and semi-gloss ranges. The interior paint, on the other hand, comes in gloss, semi-gloss, velvet, and other touches, enlivening the interior walls, ceiling, and furniture.

Raw Materials to Manufacture Acrylic Emulsion Paints

As read above, in the process of acrylic paints, manufacturers make use of 4 main ingredients. Let us understand these raw materials below.

- Pigment

Pigment refers to the color element of the paint, i.e., it defines the final hue of the paint. This pigment can be both organic and inorganic.

- Coagulant

It refers to that substance in the paint’s composition that clusters small particles and ultimately forms the drops of paint.

- Emulsifier

Emulsifier is the binding agent in paints. It binds the pigment/color to the water so that the color distributes properly in the mixture, and a well-blended paint can be created.

- Water

Water is used to mix all the contents/ingredients together to develop an effective paint.

Manufacturing Process of Acrylic Emulsion Paints

In the making of acrylic emulsion paints, manufacturers follow the following process:

In UEC’s paint plant machinery, mix the pigment with water and let it disperse. Once the pigment gets wet and starts dispersing, you will be able to comprehend if there is a need for more pigment or water. Pour the required substance, if required.

After this, add an emulsifier (the binding agent) to the liquid mixture. An emulsifier helps bind all the contents together and disperse the pigment effectively. Once it's done, add a coagulant agent to the mixture. A coagulant will bring the small unsettling particles together with the bigger and heavier ones and allow easy blending.

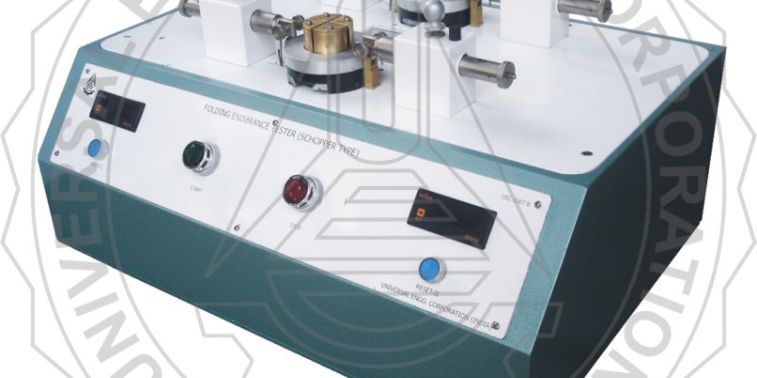

Once the entire range of ingredients (in appropriate quantities) is mixed well in the paint plant machinery, the resultant paint is taken out. The next step is to test the following parameter of the paint.

- Viscosity

The viscosity of paint defines how dense or thin it is. High viscosity means that the paint is thick and slow-moving, while a low viscosity paint will suggest a thinner paint.

- Hot-box stability

To test this parameter, the paint is kept in the oven at 60 degrees for about a month’s time. When the initial and final viscosity of paint is compared, the resultant difference determines its accelerated storage stability.

- Opacity

The opacity of the paint determines the paint’s ability to absolutely diminish/hide the color of the surface. To test this parameter, the paint is applied to a shiny opacity surface.

- Scratch resistance

To test the scrub resistance, the paint is applied to a primed glass surface and allowed to dry. After the surface is dried, the operator scratches the surface to perform the test.

- Resultant Color

It is important to test if the resulting color matches the expected color, as that submits that the mixture contains a suitable percentage of pigment.

- Adhesion/ The Ability to Sustain

The adhesion test is among the most essential tests after the paint preparation. It determines the paint’s resistance to separation from the surface, and hence the quality of the paint produced.

So this was all about acrylic emulsion paints and their manufacturing process. It is significant to test the quality of paint on development. This ensures the appropriate use of ingredients for the desired usage and also the high performance of the paint plant machinery.

As we discussed at the top, the emulsion paint manufacturing market foresees successful growth in the coming years. What we can expect is higher production of these paints and greater sourcing of paint manufacturing plants.

UEC is a leading acrylic paint plant manufacturer in India supplying high-quality paint manufacturing plants to numerous paint manufacturers. If you’re a paint manufacturer and looking to invest in one, it is time to connect with us and opt for a free demo. Please also visit the website to know about the range of products UEC provides.