Porosity is a crucial characteristic of paper, particularly in tissue paper. It refers to the fine openings within the paper structure that facilitate the passage of air and moisture. This property is important for tissue paper in terms of its absorbency and functionality. High porosity makes tissue paper ideal for personal care and cleaning applications.

In addition to porosity, smoothness is another crucial property of paper that affects its printability. An ideally smooth surface is one where all elements lie in a single plane, resulting in sharper, consistent, and high-quality prints. Similarly, softness is a measure for hygiene tissue products as it is perceived to be a key factor in consumer purchases. A soft surface provides insights into the material’s cushioning and delicateness. For hygiene tissue products (specifically bath tissue), this property can influence prices.

Instruments to measure porosity, smoothness and softness:

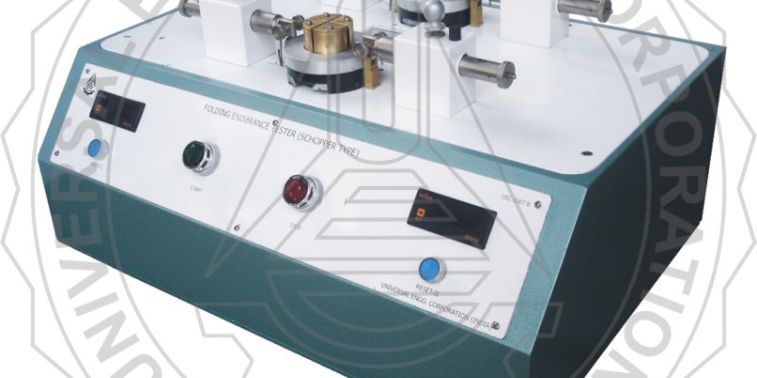

UEC-1012 A: Porosity Tester - Densometer (Gurley Type)

The Gurley Air Permeability Tester is a commonly used tool to measure the porosity or air permeability in paper and paperboard. The equipment determines the air resistance of a sample by measuring the time required for a specific volume of air to pass through it under low and uniform pressure.

UEC-1012 B: Smoothness, Porosity & Softness Tester (Gurley Type)

Users looking for added measurements of smoothness and softness opt for the Gurley Smoothness, Porosity and Softness (SPS) tester. The equipment is based on the same airflow principle over the paper’s surface under a low and uniform pressure to quantify the measurements. Interchangeable plates allow users to switch between smoothness, porosity, and softness measurements easily. Results obtained from the Gurley method are displayed on a timer in seconds for a certain volume of air that has passed through the sample.

UEC-1013: Roughness & Porosity Tester (Bendtsen Type)

Another popular choice for customers is the Bendtsen Roughness and Porosity Tester. Roughness, which is an inversely related property to smoothness, refers to the degree of unevenness in the paper’s surface. For instances where texture is desired, such as in arts and crafts, a rough paper can be used. The measurements from this equipment are also based on the airflow principle.

A controlled volume of air is passed through the sample through specially designed heads that quantify the results in milliliters/minute. Interchangeable heads allow the user to switch between roughness and porosity measurements easily. The tool’s effectiveness is widely appreciated.

Although Gurley and Bendtsen methods focus on the same airflow principle, the results are expressed in different units. Studies and trials indicate no direct correlation between the two measurements. However, the results are crucial in evaluating the paper’s evenness and uniformity, a property especially useful in printing applications.

Understanding how paper behaves in different applications is crucial for paper product manufacturers. Measurements from these instruments can help them understand several factors such as the paper’s ink absorbency, printability, permeability, smoothness, and softness. With the data, users can make informed decisions on their ink consumption, its transfer on paper, aesthetic appeal, and any quality issues that may arise. Explore more details of our options today by reaching out to us on our official communication details. For any queries or questions, do not hesitate to submit an enquiry on our website.