Just like the many paper testing parameters, stiffness is also a crucial property of paper and paperboard. It is in fact one of the most important properties of packaging papers and solid fiberboard.

In simple words, stiffness refers to the resistance of paper to bending or elastic deformation. It is defined as the bending moment per unit width of the sample. Often expressed as Sb, the paper stiffness is typically measured via a stiffness test, using a stiffness tester.

The stiffness property of the paper largely depends on the amount of fiber in its composition and its end-use application. The composition and physical characteristics of paper and paperboard are different. The paperboard has higher flexural rigidity, hence the bending resistance or stiffness is greater.

Be it paper, board, or other flexible material, manufacturers must measure this property using high-quality stiffness testers. The following section describes the 3 most sought testers by UEC. So, let’s quickly learn about them one by one.

Let us understand some valuable terms relevant to this test, before moving ahead.

- Bending moment

The bending moment refers to the effort required to deflect the specimen under specified test conditions.

- Bending resistance

Resistance to bending refers to the force required to deflect and deform the test specimen through a particular angle. The test sample is clamped at one end to perform the test. The bending resistance varies with the change in angle, the width of the sample, and the distance between the clamp edge and the application of force.

- Stiffness

When determined by a stiffness tester, stiffness refers to the degree to which paper can withstand bending, when it is subjected to a bending force. The bending force either refers to one applied during the intended use or during the stiffness test on a stiffness testing instrument.

Testing the Stiffness or Bending Resistance of Paper/Board

As we read above, the stiffness test is performed to measure the bending resistance of the paper and board. It also determines the bending moment required to deform the free side of the clamped sample when the load is applied from a specified angle on its opposite end. It is through the bending moment, the bending resistance is calculated.

To perform the test and get accurate results, paper/board manufacturers invest in stiffness testers manufactured by UEC. UEC houses three types of high-performance stiffness testers and in this article, we are going to learn about them.

Types of Stiffness Testers at UEC

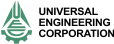

1. Taber Type Stiffness Tester

- The Taber-type stiffness tester precisely evaluates the stiffness and resiliency properties of paper and other materials up to 10,000 Taber stiffness units.

- It is authorized under standards TAPPI 489 m-69, ASTM D-747-61-T, and JIS P-8185.

- The testing equipment weighs 8.350 kilograms and comes in dimensions 24 x 28 x 41.5 centimeters.

- Each sample is prepared using a triple shear cutter. The sample cutter prepares the samples rapidly, with accuracy, and without any deformation, so that the test can be performed effectively. Manufacturers must opt for this cutter while purchasing the Taber-type stiffness tester. The cutter weighs 2 kilograms approx.

- The test measurement accuracy comes up to ±1.0% for test samples of 0.004"- 0.219" thickness at angles 7 1/2° or 15°.

- Manufacturers can opt for calibration standard strips too in addition to the tester.

- The tester can evaluate the stiffness of writing or printing paper, duplex and art paper, Kraft liner, paperboard, metallic sheets, plastic, and likewise flexible materials.

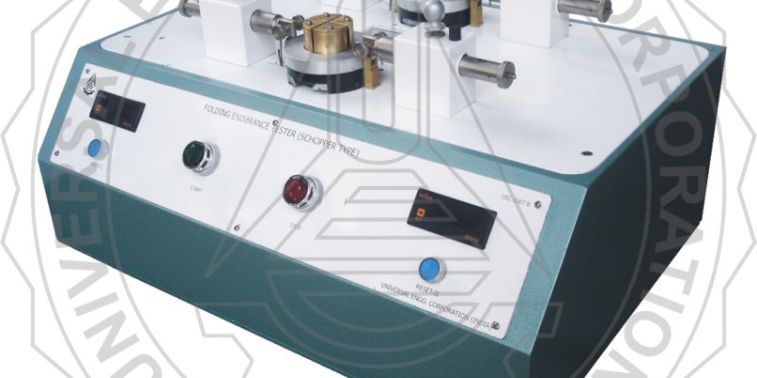

2. Digital Stiffness Tester

- The digital stiffness tester is a user-friendly equipment, that offers an easy-to-operate functionality.

- It is authorized under standards ISO 2493, DIN 53121, BS 3748, NF Q 03-048, SCAN P29, and TAPPI T 556.

- The testing instrument weighs 14 kilograms and comes in dimensions 31.5 x 34 x 29 centimeters.

- It comes with robust clamps, which fasten the test specimen rigidly to achieve accurate results.

- Once the sample is fastened, maximum force is applied to the piece to bend it to a specified angle. Both the force and stiffness values get displayed directly on the digital panel.

- Its measuring range varied between 0 and 5000 m N.

- A triple-shear cutter is used to prepare the samples, just like for the Taber-type model.

- Manufacturers can opt for calibration standard strips and standard calibration check weights in addition to the tester.

- The tester can evaluate the stiffness of writing or printing paper, duplex and art paper, Kraft liner, paperboard, and similar flexible materials.

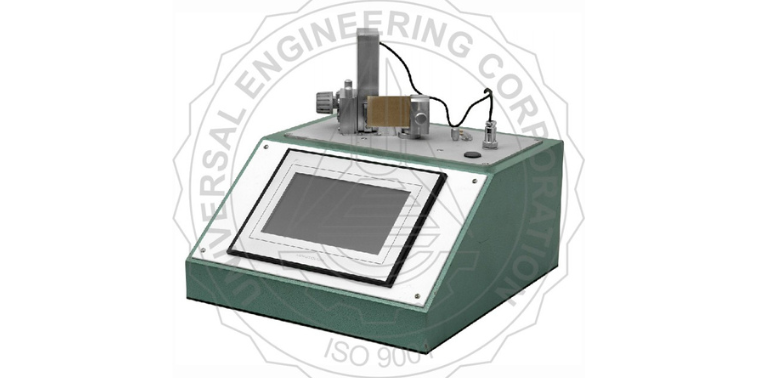

3. Touch Screen Stiffness Tester

- The touchscreen model of the bending stiffness tester is a user-friendly HMI-operated instrument.

- It is authorized under standards ISO 2493, DIN 53121, BS 3748, NF Q 03-048, SCAN P29, and TAPPI T 556.

- The tester weighs 14 kilograms and comes in dimensions 31.5 x 34 x 29 centimeters.

- The clamps in the unit fasten one end of the test sample, and then maximum force is applied to bend it to a specified angle.

- All the individual values, statistics, functions, and ratios are displayed on the HMI panel as soon as the test completes.

- The measuring range ranges from 0-5000 m N and 0-10000 m N.

- Just like the above two stiffness testers, a triple-shear cutter is used to prepare the samples in the touchscreen model.

- Manufacturers can also opt for calibration standard strips and standard calibration check weights in addition to the tester.

- The tester can evaluate the stiffness of writing or printing paper, duplex and art paper, Kraft liner, paperboard, and similar flexible materials.

The bending stiffness is a significant parameter in paper testing. In addition to the GSM and thickness, the stiffness also plays a great role in determining the quality of the paper and paperboard. If you’re a paper manufacturer and looking for a high-performance and user-friendly stiffness tester that offers accurate results, invest in UEC’s stiffness testing instruments.

Visit UEC’s website www.uecin.com to know more about other paper physical property testing equipment. Share your inquiries, connect with the experts, and request demos of the best testing instruments.