Good sample preparation is crucial in ensuring the accuracy, reliability, and consistency of test results.

- Proper sample preparation ensures that samples are representative of the material being tested and are cut to the correct dimensions. This helps in obtaining accurate measurements and reliable test results.

- Uniform sample preparation eliminates variability between samples, allowing for consistent and comparable results across multiple tests. This is essential for validating quality and performance standards.

Overall, good sample preparation is fundamental for achieving valid test outcomes, ensuring material performance is evaluated accurately, and informed decisions can be made based on the test data.

Sample Preparation Cutters Offered By UEC

Universal Engineering Corporation’s (UEC) Precision Sample Cutters are designed for efficient and rapid preparation of test pieces used in numerous tests including tearing, bending resistance, tensile, ring crush, edge crush, ply-bond, water absorbency, short span and folding strength test. The cutters are ergonomically designed, featuring safety enhancements to ensure secure and straightforward use across a variety of paper grades and grammages.

Our cutters are manufactured from high-grade alloy tool steel ensuring precise cuts and extended tool life. The punch and die series are known for its reliability and accuracy, making it a popular choice among customers globally. The cutters are easy to operate, either by simply pressing the hand lever or by pressing a simple push button to obtain samples of the specified dimensions.

Each cutter has its specific use depending on the type of test being performed, the precision required, and the material being cut. Our range of cutters include:

Sample Cutters for Edge Crush Test

The Edge Crush Test (ECT) is essential for evaluating the strength and durability of paper based materials, particularly corrugated cardboard. The test requires precise preparation of rectangular or dumbbell shaped samples of corrugated fiberboard.

A test piece is placed on an emery lined surface under the twin knife cutter which is operated with a hand driven or a pneumatically operated mechanism. The two knives cut the sample along the top and bottom edge in perfectly straight parallel lines. The cutter is available in various sizes, including samples of 1” and 2” width. Customized sizes to meet customer specifications are also available on request.

Punch and Die Cutters

A comprehensive evaluation of paper quality requires performing several tests that provides vital information about the paper’s performance.

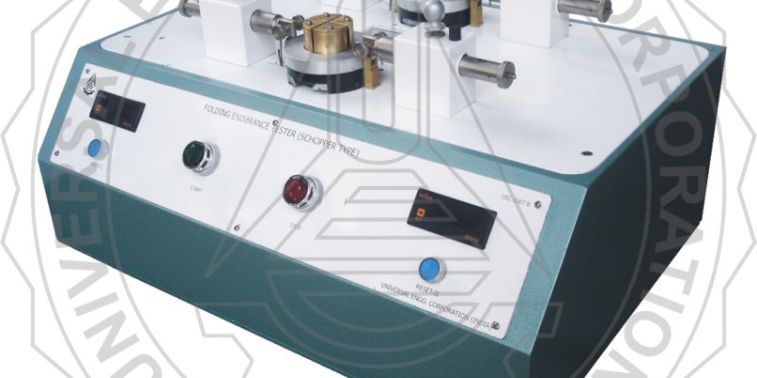

The Folding Endurance test measures the paper’s resistance to repeated bending that is crucial for products like currency and maps that undergo frequent handling and flexing. Another widely conducted test for evaluating the paper’s strength is the tensile test that determines the force required to rupture a paper strip, measured in both machine and cross direction. It is useful in understanding how well the paper can withstand stretching forces.

For paperboard samples, one of the most important tests is the Short Span Compression test that measures the compressive strength of liners and flutes over a short span length, utilizing precise clamping mechanisms to prevent buckling.

This method is slowly replacing the traditional test method of Ring Crush Test (RCT) that measures the compressive strength of similar samples over a longer span. With this, the users can get insights into the stacking ability of corrugated boxes so that stronger boxes can be made using less raw material.

Additionally, the Internal Bond Test evaluates the adhesive strength between layers of laminated paper or paperboard, which is crucial for maintaining the durability and integrity of multilayer products. However, one of the most essential quality tests is the Grammage Test that plays an important role in determining the thickness, weight and overall quality of paper.

It is often the first and simplest tests to conduct. It quantifies the paper’s weight per unit area, expressed in grams per square meter (g/m²). This test is conducted under specific temperature and humidity conditions to ensure consistent and accurate measurements.

The Punch and Die Cutters are used to rapidly prepare paper and paperboard samples according to the tests mentioned above. A sample is inserted in to the test area and is punched by pressing the hand lever with light force or by pressing a push button. The cutter clamps the sample prior to cutting action and precisely cuts it to the required size without causing deformation or damage.

The user retrieves the sample from the sample collection tray which can then be used for carrying out tests. These cutters are designed to cut multiple samples simultaneously in one cycle which reduces the sample preparation time significantly.

Our range of Punch and Die Cutters comes in the following sizes according to the required test or customized according to user needs.

Sample Cutters for Tearing and Stiffness Test

The Tearing test of paper is a key quality control method in the paper industry, measuring how well paper and board resist to the tearing forces. By applying a controlled tearing force to a standardized specimen, this test provides an understanding of the material's durability and strength whereas the stiffness test evaluates the paper's resistance to bending under a specific load, essential for its performance in various applications like packaging and printing.

This test often uses the Taber method, which measures deflection or bending when a known load is applied. The test results are reported in millinewtons (mN) or grams (g).

The cutters for Tearing and Stiffness tester from UEC are globally recognized for its precision and durability. These cutters are made from high grade alloy tool steel that provides exceptional performance. Our range of cutters include the following:

Selecting the right type of sample cutters for your testing needs is crucial for accurate and reliable test results. Thus, investing in high-quality, specialized cutters manufactured by Universal Engineering Corporation will not only improve your testing efficiency but will also give accurate insights into the overall performance of your products.

To know more about our products please visit our website at www.uecin.com. You may share your queries through email or submit an enquiry form to get a prompt answer.