A package is tested for various parameters before it gets approved by the manufacturer for end use. This is because the package does not just have to protect itself but also the products inside it during handling, shipping, and even storing.

We as a manufacturer and supplier of package testing equipment find ourselves responsible to cater to the needs of the different product-selling businesses. Therefore we make robust, high-performance, and accuracy-driven package testing machines that contribute to optimizing the production of paper and its products.

Out of the wide range of package testing machines that UEC offers, we are going to throw light on the two significant testers in this article.

Both these testers allow manufacturers to get an insight into the abilities of the packaging material and how it will perform during transportation and handling. Let us know what these impact and drop parameters are and how they are evaluated using UEC’s exclusive testing machines.

Significance Of Impact & Drop Tests in the Packaging Industry

Impact Test

Impact means the effect of something on the other especially when the former comes forcibly in contact with the latter. In the packaging industry, it means the same. When a package goes through storage, handling, and shipping, it may come under an unwanted impact, which may lead to its rapid deformation.

The impact test evaluates if the package is durable enough to withstand an impact. In other words, it tests the toughness, hardness, and strength of the box and how it’ll react during impacts.

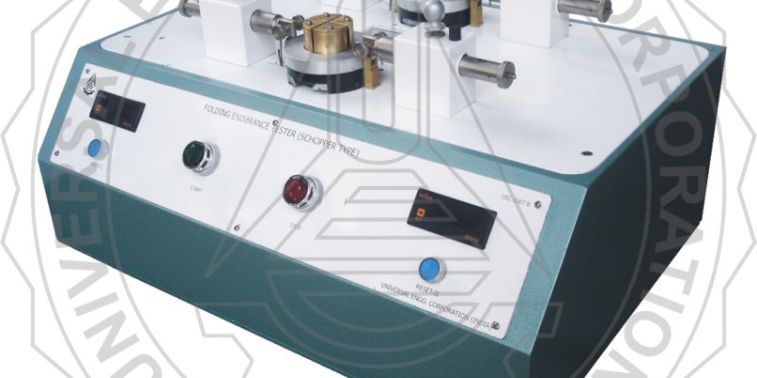

Manufacturers use UEC’s Impact tester to perform this test. Let’s read below the functionality of this equipment.

- Manufacturers can go for customized models available in different capacities from 600 to 6000 pounds.

- It comes with an automatic release mechanism and a traveling chain too

- A control panel, mounted on the equipment, operates the unit and its drive motor.

- It has a rugged built design that can be used continuously without any wear and tear.

- UEC houses a Conbur incline type Impact tester to determine the impact strength of the corrugated boxes or containers composed of cardboard, wood, or even plastics.

Drop Test

Drop simply refers to the fall of a packaging box from a particular height. It could be a free-fall, a tumble, or else. In the packaging industry, it refers to the falling or tumbling of a packaging box during shipping, handling, and distribution.

The drop test is performed to significantly know the strengths and weaknesses of the box. It determines if the box is able to withstand the hit when dropped from a specific height and at a specific orientation i.e. corners, faces, and edges.

Manufacturers use UEC’s Drop tester to perform this test. Let us now have a look at how it works.

- UEC’s automatic drop tester is approved under ISO 2248 A and AS 2582.4 standards.

- It determines the ability of the package to resist drops, falls, or any rigors during handling.

- During the test, the operator observes the physical impact on the package when it is dropped from a particular height and in a particular position.

- The main testing unit is located on a strong base plate, which is motorized and sets the drop height and lifts the packaging box.

- The height display panel displays the height digitally and the pneumatically operated foot switch releases the package.

- The maximum drop height is 1650 mm and the box weight is 110 lbs. Manufacturers can choose customized drop height and weights too.

Package testing equipment proves extremely useful for the manufacturers of packaging materials. By investing in reliable package testing machines, manufacturers make sure that the offered packaging materials are high-quality and excellent in safeguarding the products till delivery.

UEC offers the most trustworthy and high-performance machines. Connect with us to explore a wide range of pulp, paper, and packaging testing instruments.

You can also opt for a quick demo before investing.