Bursting strength is a crucial property of paper, paperboard, and corrugated board for assessing their durability to withstand maximum pressure before they rupture. It is measured by applying a controlled hydraulic pressure to a sample of paper, paperboard, or corrugated board until it bursts.

The pressure at which the material gets ruptured is said to be its bursting strength. The test results of bursting is expressed in kg/cm2 or in pounds per square inch (PSI) units. Bursting Strength testing is considered to be a significant parameter for evaluation of paper, paperboard, and corrugated board since the material that has poor bursting strength directly influences the performance of packaging, its quality, and economic efficiency.

UEC’s Bursting Strength Testers are based on the Mullen principle and come in various models depending on the user’s budget and required test reporting parameters. The product line begins with a basic hand wheel clamping model that shows measurements on a bourdon pressure gauge and extends to the advanced NexGen touch screen model, which incorporates cutting-edge technology to deliver precise results and a graphical display of the data obtained.

It offers enhanced usability, repeatability and a true representation of the sample’s performance. Additional features such as automatic clamping, configurable test parameters, wireless PC connectivity and comprehensive test reporting gives key insights into the test results instantly. All of this increased efficiency allows mills to make timely process adjustments and optimize raw material usage.

Variants:

UEC-1010 A1: Bursting Strength Tester for paper (Lever arm clamping)

Users with budget constraints who wish to assess fundamental bursting characteristics, such as maximum bursting strength, are advised to choose the UEC-1010 A1/B1. This compact unit operates through a simple push button operation. The sample is clamped with a handwheel and the maximum pressure of the paper, paperboard or corrugated board sample at the time of rupture is recorded on a bourdon pressure gauge.

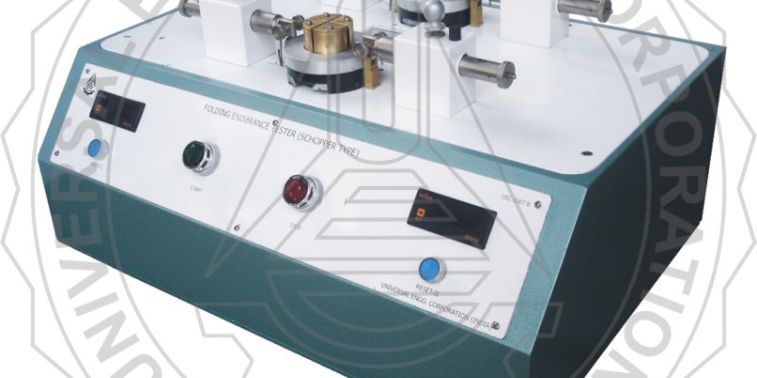

UEC-1010 B2: Bursting Strength Tester for board & solid fiber corrugated board with digital display (hand wheel clamping)

The next upgrade is our digital Bursting Strength Tester (UEC-1010 A2/B2) equipped with hand wheel clamping but with a digital control panel. Users now have the capability to feed the GSM of paper, save the test data and obtain results including the mean of Bursting Strength and Burst Factor. The diaphragm after rupture, returns automatically upon completion of the test.

UEC-1010 C1: Bursting Strength Tester keypad operated for paper/paperboard (Pneumatic clamping)

Our range of burst tester just doesn’t end here. The Bursting Strength Tester with pneumatic clamping (UEC-1010 C1/D1) is the preferred option among customers. The unit is microprocessor based and comes complete with memory for retaining peak value. It has automatic zero setting and overload and over travel protection facilities. Automatic clamping of the test specimen also allows for quick operation, uniform clamping across specimen and improved repeatability of tests.

UEC-1010 C2: Bursting Strength Tester touchscreen controlled for paper/paperboard (Pneumatic clamping)

Users can also upgrade to the NexGen touchscreen control system (UEC-1010 C2/D2) that not only provides a graphical representation of test results but also reports additional test parameters beyond the Bursting Strength and Burst Factor.

The newly developed platform provides a high level of detail on the sample including its Burst Strength Index, Bust Energy Absorption, Burst Energy Absorption Index, maximum and minimum value, standard deviation and coefficient of variation. The software allows configurable test parameters, live monitoring of test results, comprehensive data analysis, wireless connectivity, auto cycle operation and many more.

The upgrade provides key data insights which are often overlooked or difficult to measure. With this option, users can perform hundreds of tests rapidly and make accurate data driven decision to optimize their process.

UEC-1010 E2: Double headed Bursting Strength Tester touchscreen controlled for paper and corrugated board (Pneumatic clamping)

For users looking to test paper/paperboard and corrugated board samples in one equipment, our Double Headed Bursting Strength Tester with pneumatic clamping (UEC-1010 E1) is an ideal choice. The unit offers the same functionality as the Bursting Strength Testers with pneumatic clamping but has slight modifications to the software to include operation of both heads from one digital control panel.

Similar to the previous model with a singular head, this model can also be upgraded to a touchscreen-controlled system that provides an extensive reporting of results along with a graphical representation of data points. The test results can also be printed or downloaded as a PDF or spreadsheet with just a single click.

With this upgrade, users save considerable investment and time to perform independent calculations on different testers. Low and high GSM samples can be tested rapidly on the two heads with just a few clicks and allows the user to generate a detailed report on a single page.

UEC’s vast offering of Bursting Strength Testers for paper, paperboard, corrugated board and fiber board samples will not only provide users an important understanding of the sample’s performance but will help them make informed decisions into their processes or supply chain.

With a variety of offerings available, users can invest depending on their budget and testing needs. Explore more details of our options today by visiting www.uecin.com or by reaching out directly to us on our official communication channel. For any queries or questions, do not hesitate to submit an enquiry on our website.